Hole saws are circular drill bits designed to create perfect holes in materials such as metals, woods, and plastics. They operate a little differently from your standard handheld power drill, so it’s important to read up on how to use them – and spend a little time practising the technique – before you begin your project.

If you’re a first-time hole saw user, or you’re looking to invest in your first hole saw kit, this buyer’s guide will teach you what to look out for and how to stay safe when using hole saws.

What is a Hole Saw and What is it Used for?

A hole saw, also known as a hole cutter saw, is a handheld power tool you can use to cut precise circular-shaped voids through materials like plastic, wood, metal, and drywall. Like the holes they create, hole saw bits are perfectly round and come in a range of sizes – which correspond to the exact diameter of the hole size they make.

Unlike standard drill bits, which create a small and precise hole by boring into the source material, hole sawing cuts around the circumference of the hole, leaving the inner core intact. This solid core – commonly referred to as a slug – either pops out with a little push from an ejector spring (if your drill bit is fitted with one) or it comes away when you pull your hole saw out of the hole.

Parts of a Hole Saw

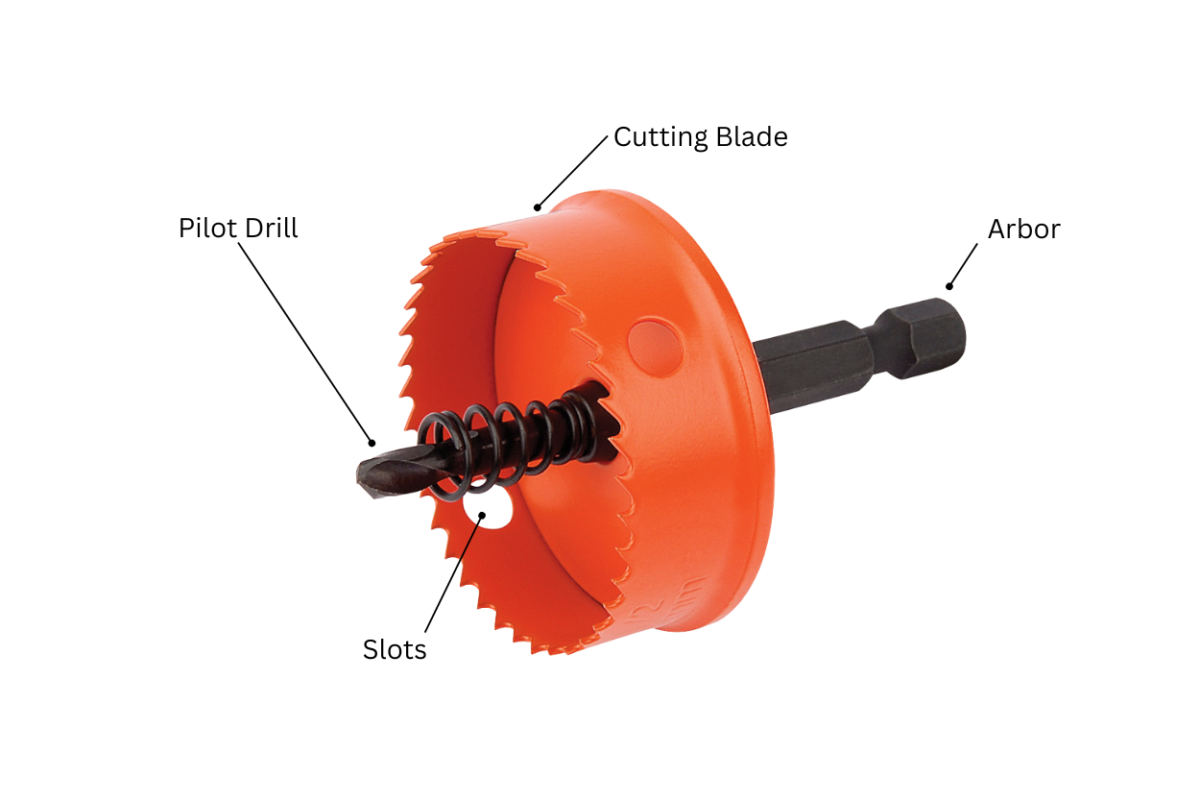

Hole saws consist of cutting blade, slots, a pilot drill, and an arbor. The arbor is the connecting piece that attaches the hole saw drill bit to the drill chuck. We go into more detail about hole saw arbors further down in this guide.

Hole saw drill bits feature rows of teeth around the outer circumference of their blade. These teeth will either be spaced out at different distances (known as variable pitch) or the same distance all the way around (known as constant pitch).

As well as teeth pitch, each hole saw drill bit also comes with differing TPIs (Teeth Per Inch). As a rule, higher TPIs result in a smoother finish but take longer to cut. Conversely, a lower TPI will cut the hole quicker but the result won’t be as finessed.

The other notable feature of a hole saw bit are the slots sitting on either side of the body. These are there to allow dust and chips to escape from the cylinder as you work, helping to prevent material-build up that can lead to clogging.

Types of Hole Saws

Hole saws come in two types: Bi-metal and tungsten carbide. The main difference boils down to cost and durability.

Bi-metal hole saws are manufactured from a blend of steels. They retail for less than tungsten carbide hole saws, but aren’t as durable, so they’re not suitable for use with materials like tile, glass, masonry or some hard metals.

Tungsten carbide hole saws, on the other hand, comprise of pure, unblended tungsten carbide. They cost more than bi-metal hole saws, but they offer greater durability, so they’re able to withstand more hardy materials and a wider scope of applications.

How to Use a Hole Saw?

Hole saws can be a little tricky to master, but once you’ve nailed the technique you should have no trouble creating perfectly sized voids in all kinds of materials. The same basic operating principles apply, no matter if you’re cutting through metal, plastic, or wood.

Here are the key steps you need to take, to work safely and smartly with hole saws:

- Start any hole sawing project by drilling a pilot hole at the centre point of your hole.

- Place the hole saw’s drill bit into the pilot hole you’ve created.

- Using both hands to hold the drill, begin slowly drilling your hole, just enough to create a shallow surface cut in the material.

- Gradually increase the speed of your drilling and maintain this steady pace – without applying pressure – until the hole saw drill bit pushes though the opposite surface of your material.

- At this point, stop your drill and once the bit has stopped rotating, carefully remove the drill from the hole you’ve created.

- If the plug or slug from the hole is wedged inside of your hole saw, simply disconnect the power source, to cut off the electricity supply to the drill, and then push a screwdriver through one of the slots to gently jimmy the slug out.

Different Applications of Hole Saws

With their ability to create perfect holes of varying sizes, it’s not surprising that hole saws are used by a range of trade professions for a wide scope of applications. Some of the most common hole saw uses include:

- Hole Saws for Metal

Hole saws for metal need to be hardwearing and temperature resistant, so you’ll be looking at tungsten carbide bits for this application. Metal hole saws are typically used for manufacturing or automotive purposes.

- Hole Saws for Wood

Hole saws for wood are great for DIY jobs and general joinery at home. They’re also extensively used by carpenters for the purpose of adding hardware like locks to internal doors, or by electricians for making openings in ceilings for light fixtures.

- Hole Saws for Concrete

Concrete compatible hole saws are used in the installation of pipework and cabling in walls, as well as for ventilation and waste removal purposes. They’re a common part of a professional plumber’s and electrician’s toolkit, and their teeth are usually veritable in pitch to help to cut through toughened materials easily, and with less vibration.

- Hole Saws for Glass

Hole cutter saws for glass often feature widely spaced, square-edged teeth. This design creates the power that’s needed to penetrate glass, albeit the finish is rough. Glass hole saws are generally required for creating vents in windows or making incisions in mirrors.

- Hole Saws for Tile

A hole saw cutter for tiles is another popular plumber’s tool. This hole saw type is primarily used in the installation of bathroom hardware, for purposes such as drilling drainage holes and tap holes in sinks and baths. They generally have a toothless design, instead, featuring a flat rim that’s coated with a hard and abrasive material.

What is an Arbor and how to use one With a Hole Saw?

An arbor is a tool accessory that’s used to connect two rotating components. It consists of a shaft and a rotating part, and in the case of hole saws it connects the drill bit to the drill chuck. Arbors also commonly have a drill bit attached at one end. This bit is used to create pilot holes at the centre point of the hole being cut. Pilot holes help to steady the saw during operation, to prevent it from wandering.

Although an arbor isn’t required to operate a hole saw, many hole saws are sold with one. The benefits of using an arbor with a hole saw include increased stability and control, which can improve the cleanliness of the finished hole as well the ease of operating the hole saw.

Popular Hole Saw Makes & Models

Whether you’re looking to expand your hole saw drill bit collection or invest in a hole saw and arbor combo, we stock a wide range of hole saws and hole drill bit accessories for every application. Browse our online hole cutter saw range to shop the full collection or jump straight our top selling hole cutter saw types, below.

Ready to get organised?

Find your perfect tool storage from our professional range

From tool bags and tool chests to tool boxes with wheels, tool belts, tool cases, and trade-specific tool storage, at Red Box Tools we offer high-quality solutions you can count on.

Or why not take your tool storage to the next level with our made-to-order tool box foam drawer inserts and custom shadow foaming?